During the operation of power equipment, the insulation will gradually deteriorate under the action of electric field, temperature and mechanical vibration for a long time, including overall deterioration and partial deterioration, resulting in defects. defect.

Various preventive test methods, each with its own strengths, can find some defects and reflect the insulation condition, but the test voltage of other test methods is often lower than the working voltage of the power equipment, but the AC withstand voltage test voltage is generally higher than that of the power equipment. The operating voltage is high, so after passing the test, the equipment has a large safety margin, so this test has become an important means to ensure safe operation.

However, since the test voltage used in the AC withstand voltage test is much higher than the operating voltage, the excessive voltage will increase the loss of the insulating medium, generate heat, and discharge, which will accelerate the development of insulation defects. Therefore, in a sense, The AC withstand voltage test is a destructive test. Before the AC withstand voltage test, various non-destructive tests must be carried out in advance.

Such as measuring insulation resistance, absorption ratio, dielectric loss factor tanδ, DC leakage current, etc., comprehensively analyze the test results to determine whether the equipment is damp or contains defects. If it is found that there is a problem, it needs to be dealt with in advance, and the AC withstand voltage test can be carried out after the defect is eliminated, so as to avoid insulation breakdown during the AC withstand voltage test, expand insulation defects, prolong maintenance time, and increase maintenance workload. .

This test is used to verify the external withstand strength of the line end and neutral point terminals and the windings to which they are connected to ground and other windings. The AC withstand voltage test is the most direct and effective method to test the insulation strength of the transformer. It is useful for finding local defects in the main insulation of the transformer, such as the main insulation of the winding is damp, cracked or the winding is loose during transportation, the lead distance is not enough, and there is oil in the main insulation. Defects such as impurities, air bubbles, and dirt adhering to the winding insulation are very effective. The AC withstand voltage test of the transformer can only be carried out after the transformer is filled with qualified insulating oil, kept stationary for a certain period of time and all other insulation tests are qualified.

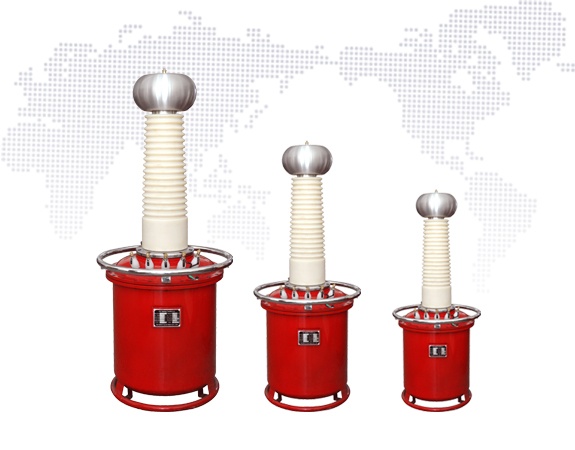

HV HIPOT YDQ series gas testing transformer

YDQ series gas type test transformer adopts new material and new technology, and uses sulfur hexafluoride as the medium. Compared with the traditional oil-immersed test transformer, the weight of the gas-type test transformer is only 40%-80% of that of the oil-immersed test transformer under the same voltage level and capacity. The voltage level of a single unit can reach 300KV, which is especially suitable for on-site operations. It has the characteristics of small size, light weight, no oil pollution, and is not affected by climate change. The corona is extremely small, the test can be done without being stationary during on-site handling, and the service life is long, and no maintenance is required.

Product nickname: YDQ AC and DC SF6 gas test transformers, gas-filled test transformers, high-voltage test transformers, power high-voltage test transformers, ultra-light high-voltage test transformers, cascade high-voltage test transformers, gas-filled test transformers, gas-filled test transformers, gas-filled test transformers, Gas-filled light-duty high-voltage test transformers.

Post time: Feb-12-2022